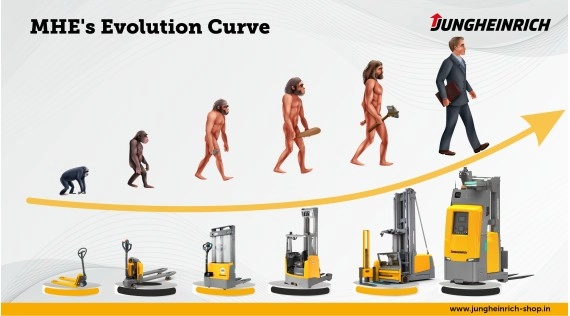

MHE’s Evolution Curve.

The evolution of forklifts in terms of size and capacity can be traced back to the early 1900s when the first fork trucks were introduced. Here is a summary of how forklifts have evolved in terms of size and capacity:

1. Manual Labor: During the Industrial Revolution in the 19th century, manual labor was the primary method of moving and handling materials. Workers would physically lift and carry objects or use basic tools like pulleys and carts

2. Early Fork Trucks: In the early days, fork trucks were basic and had limited lifting capabilities. They were designed to lift their platforms a few inches off the ground. These early forklifts were not widely used until after 1926, but improvements were made during this time, including the introduction of forks and rams for handling different types of objects.

3. Introduction of Vertical Lifting Cantilever Trucks: In 1919, vertical lifting cantilever trucks were developed, which allowed the trucks to drive right up to a stow without requiring clearance underneath for projecting front wheels. This innovation improved the efficiency and versatility of forklifts.

4. Standardized Pallet Sizes: As forklifts became more prevalent after World War I, the need for consistent pallet sizes arose. The implementation of standardized pallet sizes made it easier for forklifts to handle loads efficiently and safely.

5. Hydraulic Systems and Vertical Lifting Masts: By the 1920s, lift truck manufacturers started adding hydraulics and vertical lifting masts to forklifts. These advancements allowed for greater lifting heights and improved load capacity.

6. Increased Load Capacities: In a typical warehouse setting, most forklifts have load capacities between one and five tons. However, larger machines with lift capacities up to 50 tons are used for lifting heavier loads, including loaded shipping containers.

7. Technological Advancements: Over the years, forklifts have benefited from technological advancements, including electric power systems and improved engineering. These advancements have made forklifts more efficient, reliable, and capable of handling larger loads. For example, some top trends and innovations are Automation and AI, Fuel technology, real-time monitoring and data analysis & safety accessories etc.

In summary, forklifts have evolved from basic platforms with limited lifting capabilities to sophisticated machines with increased load capacities and advanced features. Technological advancements have played a significant role in improving the size, capacity, and overall performance of forklifts.

There are some similarities between the evolution of the forklift industry and human evolution. However, The evolution of the forklift industry and human evolution are not directly comparable because they are fundamentally different processes. As one is a technological advancement and the other is a natural biological process influenced by genetic factors. However, we can draw some parallels between the two:

Similarities:

• Both have undergone significant changes and adaptations over time.

• Both have been driven by the need to improve efficiency and productivity

• Both have been influenced by external factors, such as wars and technological advancements.