Types of Pallet Trucks

To make your day-to day life easy in warehouse, Jungheinrich offers you following pallet trucks....

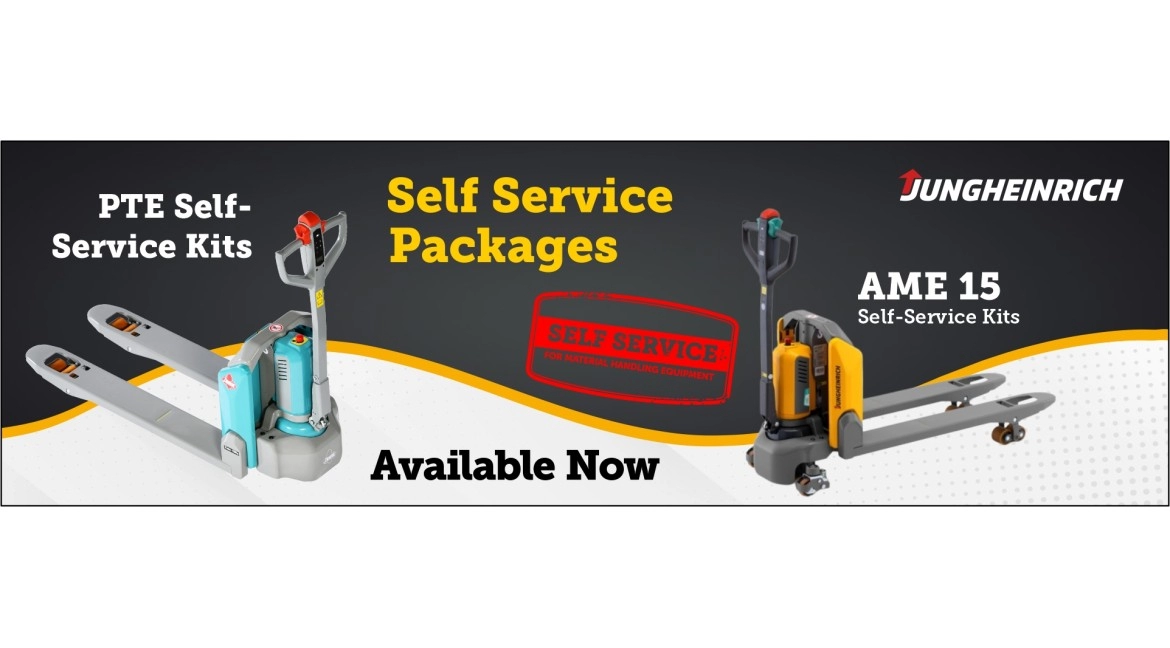

Self-Service Kits

Are you looking to carry out repairs to your industrial truck quickly, independently, and...

Warehouse Equipment Rental: A Smart Choi...

Whether you're running a warehouse, logistics operation, or any industry that requires equipment,...

MHE’s Evolution Curve.

The evolution of forklifts in terms of size and capacity can be traced back to the early 1900s...

Jungheinrich After Sales Reach

No matter where, no matter when – always ready for action!! Do you want to reduce downtime of...

How to use our online shop?

Welcome to Jungheinrich India Shop. We are here to assist you in all your Material Handling...